Memberships & Publications

To fight the climate change, hydrogen plays an important role as a transportable carrier of energy. However, in order to make the turnaround happen, a lot of challenges need to be taggled and solved, beginning with producing the amount of hydrogen needed to fulfill the energy demand.

Memberships

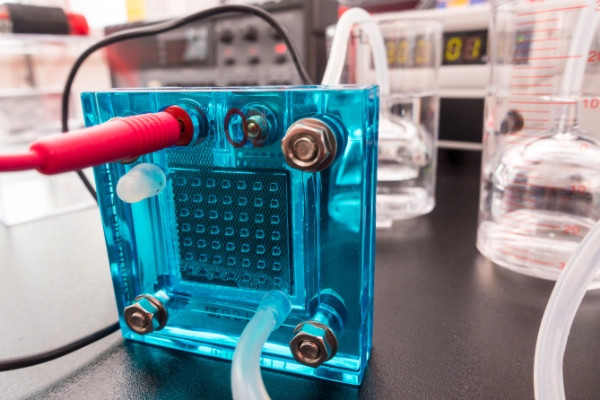

Today, most electrolytic hydrogen is produced via Alkaline Electrolysis. However, one single technology will not be sufficient to cover the complete demand. All technologies need to be employed in the best possible way. That is why Proton Exchange Membrane (PEM) electrolysis will play a particularly important role, especially in terms of production of Green Hydrogen. It is best suited to convert the fluctuating energy output of renewable energies, such as solar, hydro and wind energy.

For the mentioned PEM electrolysis precious metals are required – some of them being very scarce, like iridium – and they will be needed in significant quantities. Also, sequential processes like the purification of hydrogen, or the conversion into other forms for easier storage and transport, require precious metals.

Thus, precious metals are indispensable for the Hydrogen Revolution, and therefore the hydrogen ramp-up requires a raw material strategy. This strategy needs to cover three important aspects:

- Innovations to maximize the hydrogen output with the available raw materials or cover them with high performance alternatives, such as the Heraeus low-iridium materials

- Strategies to secure the supply with scarce materials like iridium and to manage the specific challenges like high price volatility with advanced precious metals trading services

- Additional capacities and workflows for the recycling of end-of-life materials to recover precious metals to establish a sustainable raw materials loop.

As a precious metals specialist, Heraeus is a skilled partner with high expertise in all necessary fields and has been investing significantly in R&D and hydrogen recycling. What is more, we are actively engaging in the Hydrogen Community, contributing to make the Hydrogen Revolution happen.

Heraeus is a member of various organizations that engage themselves in the Hydrogen economy, among others in the Hydrogen Council, Hydrogen Europe, Ammonia Energy Association, European Clean Hydrogen Alliance and The Fuel Cell and Hydrogen Energy Association (FCHEA).

As well, we are actively taking part in several projects to accelerate the development of solutions that enable the hydrogen ramp up.

Project length: five years

On March 13, 2024, the U.S. Department of Energy (DOE) announced $750 million in funding for 52 projects across 24 states to dramatically reduce the cost of clean hydrogen and reinforce American leadership in the growing hydrogen industry. Among the recipients, the American Institute of Chemical Engineers (AIChE) was selected to lead H2CIRC, a new “recovery and recycling” consortium charged with developing innovative and practical approaches to enable the recovery, recycling, and reuse of materials and components for hydrogen fuel cells and electrolyzers. This development will be supported by federal funding to be awarded to AIChE for the Hydrogen Electrolyzer and Fuel Cell Recycling Consortium, which totals $50 million over five years. The funding is being provided by the DOE's Hydrogen and Fuel Cell Technologies Office.

AIChE will lead a consortium that includes national laboratories, universities, and key fuel cell and electrolyzer industry partners. The project will develop and demonstrate recycling technology approaches to address end-of-life and critical supply chain challenges for proton exchange membrane fuel cells and electrolyzers. The goal of the project is to provide a blueprint for the hydrogen industry to efficiently and sustainably recover and recycle materials and components from fuel cells and electrolyzers.

Project Duration: 01.07.2023 - 30.06.2026

The ultimate goal of the UnLOHCked consortium is to exploit the full potential of LOHC (Liquid Organic Hydrogen Carrier) technology for hydrogen logistics by developing a completely CO2-free dehydrogenation plant for electricity generation. This is to be achieved by using a directly coupled technology for converting liquid hydrogen carriers into electricity and hydrogen under energy-efficient conditions and with highly optimized catalysts.

Crucial to the success of the project is the development of an innovative, cost-effective and sustainable LOHC technology with improved thermal energy efficiency in the dehydrogenation step and the development of new catalysts with high productivity and catalytic stability. The performance of the technology will be demonstrated in a LOHC dehydrogenation plant with direct thermal coupling to a SOFC (Solid Oxide Fuel Cell) for the production of renewable electricity and hydrogen. With its expertise in precious metal catalysis and its know-how in the production of precious metal catalysts, Heraeus Precious Metals is making a significant contribution to the success of the project.

Project Duration: 01.01.2023 - 31.12.2025

The R&D project PEMTASTIC aims to meet the key technical challenges to increase durability of membrane-electrode assembly (MEA) for heavy-duty applications. These challenges are approached with a combination of modelbased design and the development of a durable catalyst-coated membrane using innovative materials tailored for heavy duty operation at high temperature (105°C).

Project Duration: 01.12.2022 - 30.11.2025

The Proton Exchange Membrane (PEM) Fuel Cell (FC) technology emerging from the automotive industry is of high interest for the future aeronautic industry. However, while automotive FC systems are limited to about 100 kW, an aircraft requires a significantly greater amount of power (multi-MW). In addition, it must operate at different conditions, while being light-weight and keeping the system’s safety and reliability levels to aeronautical standards. Towards these requirements, the 3-year project BRAVA will develop breakthrough subsystem technologies (incl. catalysts, membranes, cooling systems and heat exchangers and air supply) for a FC-based Power Generation System (PGS) for aviation.

Project Duration: 01.05.2021 - 31.12.2025

Setup of a material flow for serial production of PEM electrolyzers - Adjustment and mitigation of bottle necks of refining capacities for Pt & Ir material streams, as well as closing the loop via catalyst production.

Project Duration: 01.05.2021 - 31.12.2025

Setup and expansion of recycling capacities for Pt & Ir waste streams from PEM electrolyzers in the range of GW-production. Focus on processing end-of-life electrodes – CCM (catalyst coated membrane) or MEA (membrane electrode assembly) – as well as assessment of the precious metal value the so called sampling process.

Project length: 01.04.2021 - 31.12.2025

Demonstration of the large-scale feasibility of PEM EL technology through the significant reduction of the Ir content with simultaneous highly efficient and long-lasting operation in respective MEA concepts.

Project Duration: 01.04.2021 - 31.12.2025

Stack Scale up – Industrilisation of PEM electrolysis. Reducing system invest costs via higher life-time, lower production costs as well as development of large-scale-relevant production processes.

Project Duration: 01.04.2021 - 31.12.2025

Material recycling and adjustment of precious metall qualities in dependence of new metallurgical process concepts with respect to present industrial process controlling.

Completed Projects

Project Duration: 01.10.2021 - 30.09.2024

Development of an electrochemical seperation technology for Hydrogen from the natural gas grid, aiming towards high purity.

Project Duration: 01.03.2021 - 30.06.2024

Novel bifunctional electrocatalysts for fuel cell applications.

Project Duration: 01.03.2021 - 28.02.2024

Catalyst optimization research for stable activity over life-time in heavy duty fuel cells.

Project Duration: 01.01.2021 - 30.06.2024

Electrolysis & Fuel Cell: Overall research on electrode coating processes.

Project Duration: 01.06.2019 - 21.12.2022

Development of a scalable production technology for catalyst coated membranes and membrane electrode assemblies based on robust and high volume producable electrocatalysts, which fulfil the requirements of automotive mass market.

Project Duration: 01.04.2019 - 31.03.2022

Developement of next generation PEM fuel cell as well as e electrolysis technology using sophisticated technology in bipolar plate and porous transport layer manufacturing.

Project Duration: 01.10.2016 - 30.09.2022

Investigation, validation and implementation of "Power-to-X" concepts – Technology path Hydrogen as energy vector. H2O electrolysis in PEM (polymer electrolyte membrane) electroyzers with improved efficiency , reduced precious metal loading in the electrodes and thinner membranes.

Recommended publications

You are interested in deep-diving into Hydrogen related topics? We recommend the following publications.

Dr Michael George and Dr Christian Gebauer, Heraeus Precious Metals, consider the role hydrogen fuel cells could play in the development of heavy duty vehicle materials.

| Published | Title | Topic | Author |

|---|---|---|---|

| Jan 2026 | White Paper Debunking Myths: The Role of Platinum Group Metals for a Hydrogen Future | Adressing myths with facts on the use and supply of Platinum Group Metals | Heraeus Precious Metals |

| Sep 2025 | Global Hydrogen Review 2025 | Annual publication by the International Energy Agency that tracks hydrogen production and demand worldwide, shedding light on the latest developments on policy, infrastructure, trade, investments and innovation. | International Energy Agency |

| Sep 2025 | Global Hydrogen Compass 2025 | Industry progress and lessons learned from the first wave of mature clean hydrogen projects | Hydrogen Council |

| Jul 2025 | A Call to Action: Accelerate Hydrogen Mobility for Europe’s Sustainable, Competitive and Resilient Industrial Future | CEO open letter to European Commission | Global Hydrogen Mobility Alliance |

| Jun 2025 | Conceptual Recycling Chain for Proton Exchange Membrane Water Electrolyzers—Case Study Involving Review-Derived Model Stack | Recycling of PEMWE raw materials | Bernd Friedrich et al 2025 Recycling, MDPI |

| Mar 2025 | Hydrogen: Closing the cost gap – Unlocking demand for clean hydrogen by 2030 | Report Outlines Solutions to Unlock Business Cases | Hydrogen Council |

| Jan 2025 | Electrolyser Partnership input for the Clean Industrial Deal |

Call to Actions for Hydrogen in Europe |

European Clean Hydrogen Alliance |

| Oct 2024 | Global Hydrogen Review 2024 | Comparison H2 and applications | IEA |

| Sep 2024 | Hydrogen Insights 2024 | state of the global hydrogen economy | Hydrogen Council (McK) |

| Jan 2024 | Länderanalyse 2023 – Internationale Wasserstoff-Strategien im Vergleich (country analysis 2023 – international strategies for hydrogen in comparision) | Country roadmaps, transportation routes, costs |

Wasserstoff-Kompass DECHEMA, acatech |

| Aug 2023 | A Comparative Study on the Activity and Stability of Iridium-Based Co-Catalysts for Cell Reversal Tolerant PEMFC Anodes | Material innovation for PEM fuel cells | Robert Maric et al 2023 J. Electrochem. Soc. |

| Jul 2023 | Fortschreibung der Nationalen Wasserstoffstrategie (Continuation of the National Hydrogen Strategy) | National Hydrogen Strategy Germany | Federal Ministry for Education and Research, Germany |

| Mar 2023 | Supply chain analysis and material demand forecast in strategic technologies and sectors in the EU – A foresight study | Raw materials and supply chain | Joint Research Centre, EUC |

| Jan 2022 | Mineralische Rohstoffe für die Wasserelektrolyse – Themenheft (Mineral raw materials for water electrolysis) | Availability of critical raw materials | DERA |

Read as well

Your Contact for Hydrogen Memberships & Publications