Catalysts for PEM Fuel Cells & Catalyst Coated Membranes (CCM)

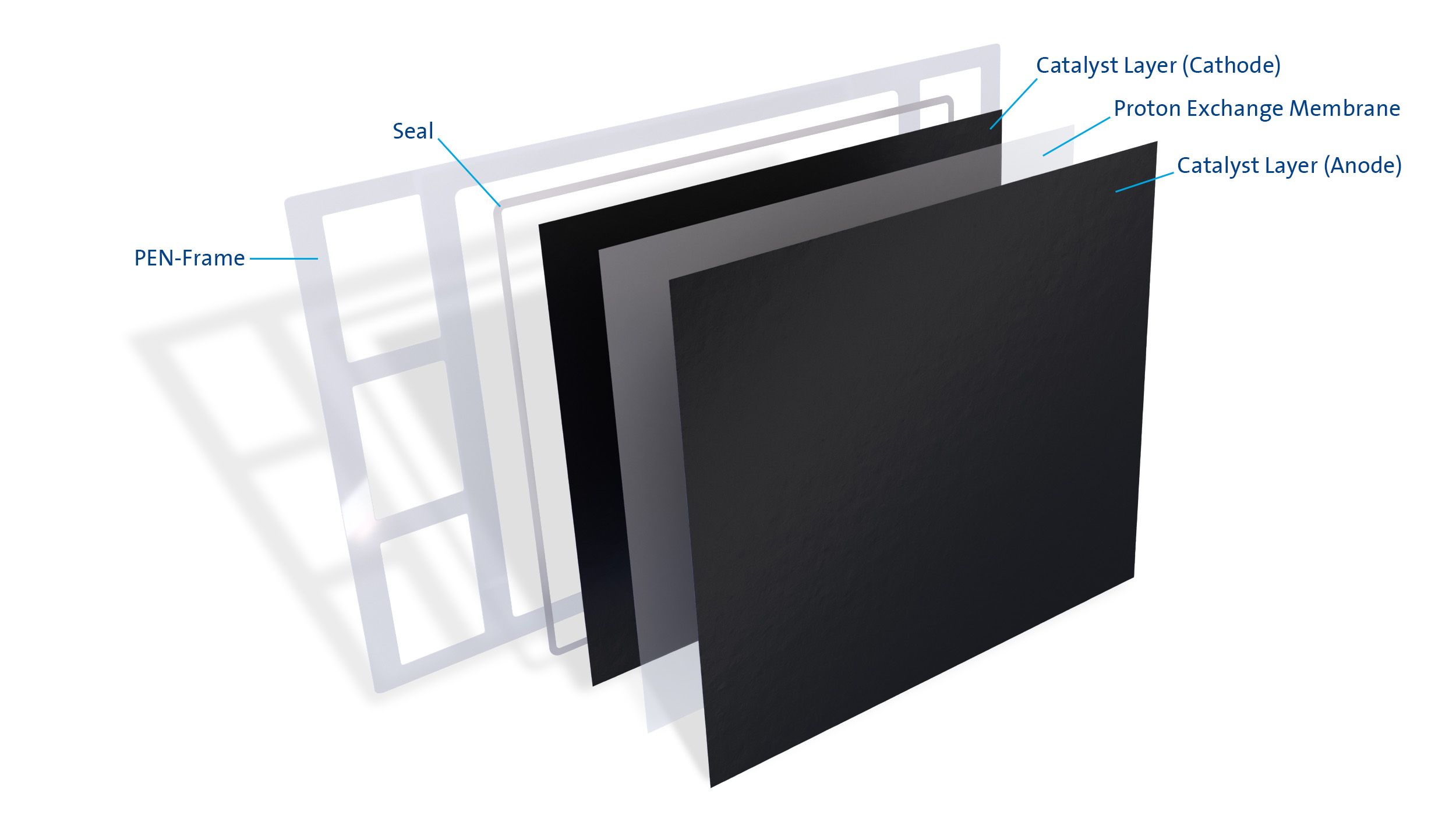

Proton exchange membrane (PEM) fuel cells convert hydrogen and oxygen into water and thereby release energy. The heart of a fuel cell is a polymer electrolyte membrane coated with platinum-based catalysts on both sides (catalyst coated membrane, CCM).

PEM Fuel Cells & Fuel Cell Operation

PEM fuel cells can be used in different mobile and stationary applications, such as power storage, material handling vehicles, light-duty and heavy-duty transport. Within the transportation sector fuel cell electric vehicles partially compete with battery electric vehicles. However, the characteristics of higher driving range and significantly lower refueling times make hydrogen fuel cell vehicles the technology of choice for long range and heavy-duty transportation.

Due to the collective commitment to the mission of reducing carbon dioxide emissions, and creating a climate neutral society, the growth of PEM fuel cells is widely foreseen. This will enable worldwide deployment of fuel cell electric vehicles and significant reduction of costs for those.

Heraeus offers precious metal-based catalysts for the cathode and the anode side of CCM for a variety of fuel cell applications, including:

- Stationary

- Material handling vehicles

- Passenger cars

- Heavy-duty transport

- Trains and buses

Heraeus’ PEM Fuel Cell Catalyst Portfolio

In a PEM fuel cell Heraeus platinum-based catalysts help to boost both electrode reactions in a fuel cell stack to form water and generate energy from H2 and O2 at various conditions on high efficiency.

Our product portfolio includes PEM fuel cell catalysts with different precious metal loadings.

In order to find the perfect solution to your needs, we are able to test in our fully equipped on-site laboratories and test center.

| Catalyst | Actydon | Pt C100 + Actydon | Ir 80 X |

Actydon | Pt C700 | Actydon | Pt M700 | Actydon | Pt 50 K700 |

|---|---|---|---|---|

| Description | 20 to 40 wt.% Pt on graphitized carbon material – optional with OER additive for even higher CRT |

20 to 60 wt.% Pt on high surface area carbon |

40 to 50 wt.% stabilized Pt on high surface area carbon |

50 wt.% PtCo on high surface area carbon |

| Highlight | High cell reversal tolerance >8000 s (15 μg Ir /cm²) (~75 s w/o OER additive)** | Optimized Pt surface utilization High ECSA | Improved Pt dissolution stability | Higher Pt-dissolution stability compared to established PtCo/C catalyst |

| ECSA [m²/gPt] | > 40 | > 70 | > 60 | > 45 |

| Cell voltage @ 0.1 A/cm² (CCM)* [V] |

~ 0.80 | ~ 0.84 | ~ 0.84 | ~ 0.84*** |

| Request More Information | online available | Request More Information | Request More Information |

*Automotive conditions **Cell reversal tolerance time until -1.25 Vcell ***At 0,2mgpt/cm2

Your Expert for Cataysts for PEM Fuel Cells

Catalyst Coated Membranes (CCM) / Membrane Electrode Assembly (MEA) for Fuel Cells

Heraeus Precious Metals advanced CCM and MEA solutions are developed to meet the requirements of modern fuel cell stacks and systems. Whether deployed in commercial vehicles such as buses and trucks, marine vessels, or stationary power units, these solutions are engineered to deliver outstanding durability, high efficiency, and long service life. Combining the know-how in stack design and system integration by Freudenberg e-Power Systems with the in-depth expertise in precious metals catalysts by Heraeus Precious Metals, we offer high alingment with modern fuel cell operation, industrial production scales and precious metals services that enable large production volumes.

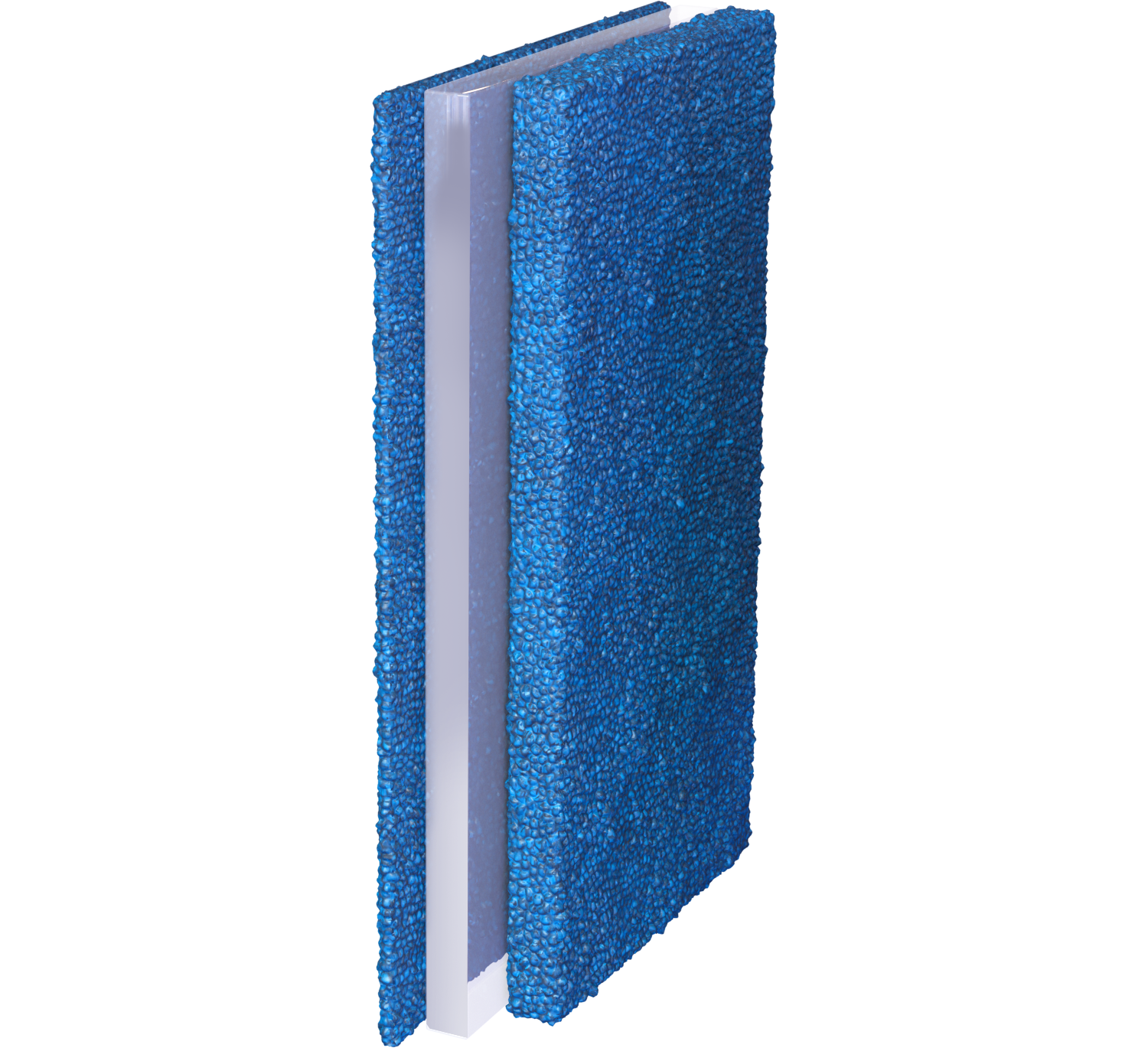

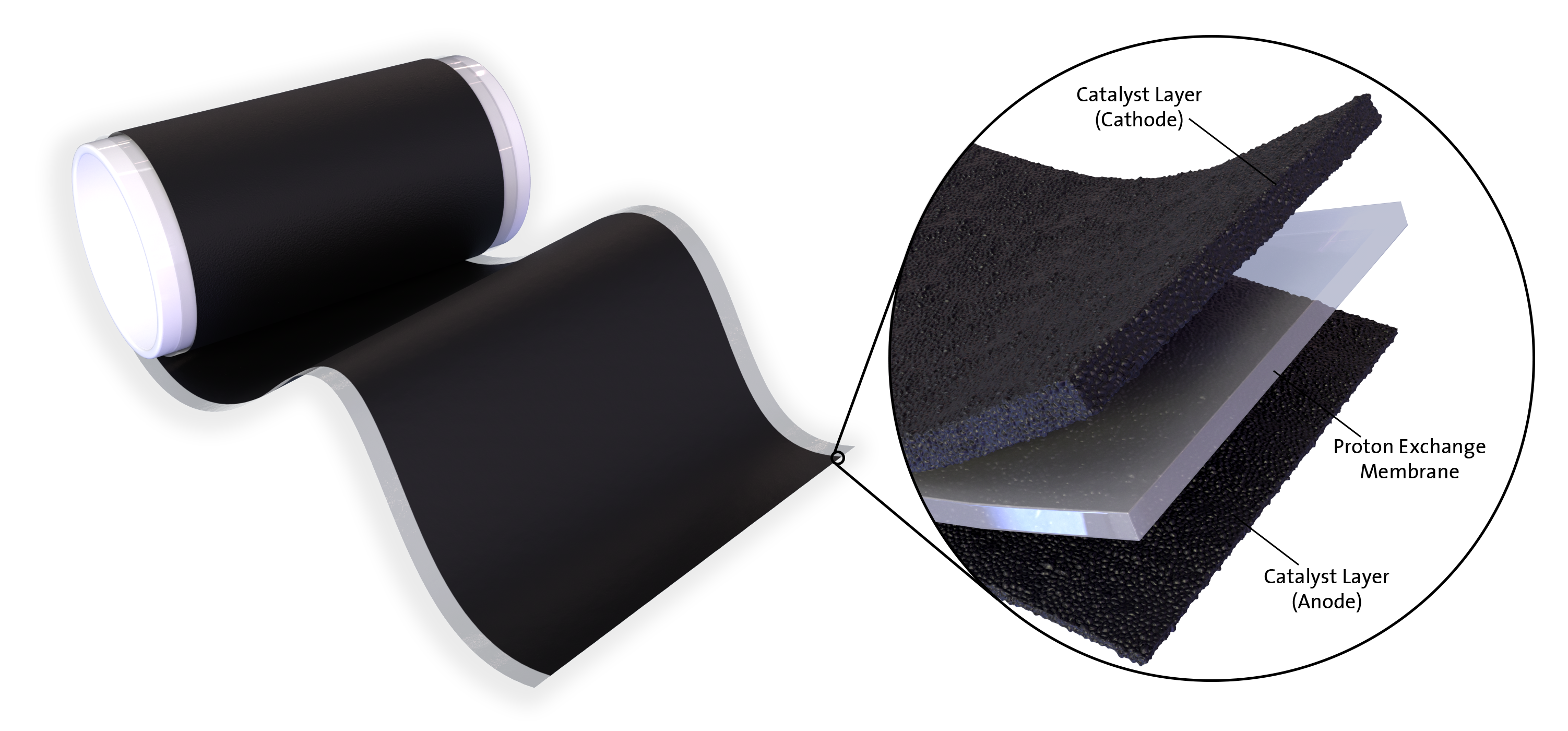

Catalyst Coated Membranes (CCM)

Catalyst Coated Membranes are critical components for fuel cell systems, as catalyst and catalyst layer design largely determine the overall system-level performance and durability. The quality of the CCM is pivotal for the efficiency, performance, and durability of fuel cells, enabling reduced operating costs over the whole lifespan of a stack.

With this partnership, Heraeus Precious Metals and Freudenberg e-Power Systems were able to create unique layer structures and catalyst particle size and distribution that enhance the performance in terms of both efficiency and durability. The performance and stability optimized CCMs thus lead to a long lifetime and lower total cost of ownership.

This results in a empirically proven CCM portfolio that addresses all aspects of commercial and technical competitiveness.

| Actydon | CCM 01 | Actydon | CCM 02 | |

|---|---|---|

| Highlight | High efficiency, flexible humidity range, high durability |

High current density, high durability |

| Cell voltage* @ 0.1 A/cm² [V] | 0.88 | 0.86 |

| Current density* @ 0.65 V [A/cm2] | 1.9 | 2.0 |

* Differential setup (RH 95%, 80 °C)

-

Efficiency: Enhanced Catalyst efficiency.

-

Durability: Extended operational lifespan with minimal degradation.

-

Automation: Highly automated roll-to-roll production processes.

-

Sustainability: Manufacturing with efficient use of resources.

-

Circularity: Holistic precious metals sourcing and recycling concept.

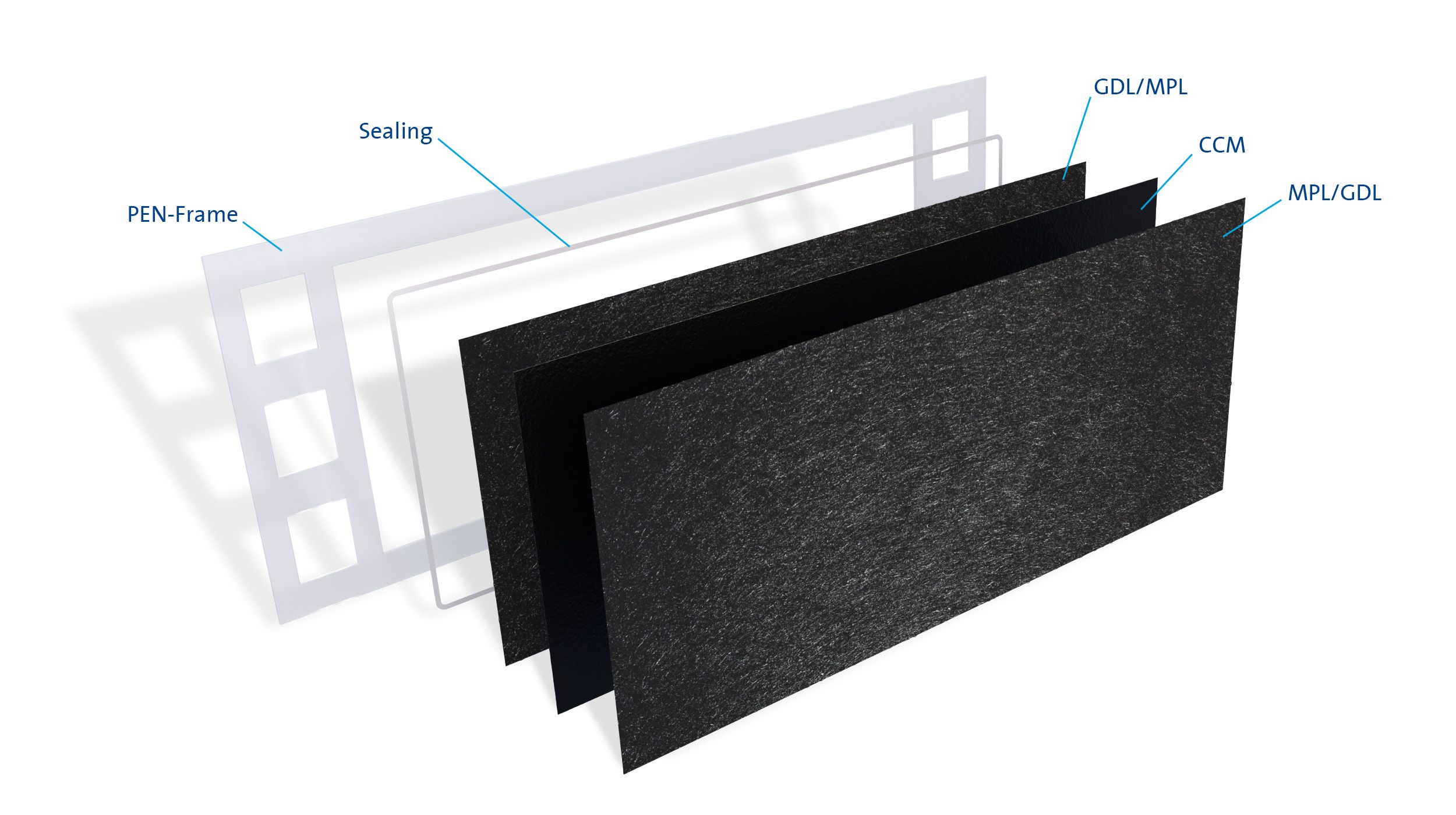

Membrane Electrode Assembly (MEA) for Fuel Cells

All high-volume catalyst-coated membrane (CCM) variants are also available as membrane electrode assembly (MEA) configurations utilizing the know-how of FEPS in sealing technologies and gas diffusion layers (GDL). The available MEA7 structure is a 7-layer structure, compried of CCMs laminated with advanced gas diffusion layers (GDLs) and customized frame. A tailored sealing solution integrates the entire cell architecture into a precisely engineered polymer frame, ensuring easy handling and efficient integration into fuel cell stacks. This sealing approach effectively eliminates gas crossover, contributing to extended operational lifetimes.

By adopting Heraeus Precious Metals’ high-volume MEA program, you gain access to the full performance advantages of the unique CCM technology while minimizing the cost for MEA manufacturing equipment. This strategy enables a reduction in the Total Cost of Ownership (TCO) for PEM fuel cells through three key avenues: a) utilization of high-performance, durability-enhanced catalysts; b) operational cost savings via the scalable production facility; and c) sustainable material management through closed-loop recycling, covering both production waste and end-of-life components.

-

Activity: Engineered GDL and MPL structures for enhanced mass transport properties.

-

Assembly: The MEA7 features a structurally reinforced design with an integrated frame, streamlining the fuel cell stack assembly process.

-

TCO: Reduction of the total cost of ownership (TCO) of PEM fuel cells through performance- and stability-optimized catalysts and electrodes, as well as expertise in metal management and recycling

-

Efficiency: Innovative precious metal deposition results in optimal platinum utilization.

-

Durability: Long lifetime for your application by using electrode layers designed for best stability and reliability.

-

Industrial Scale: Proven industrialization competence in electrochemistry. Established and highly efficient manufacturing technology with integrated quality controls.

Customized CCM and MEA

CCMs and MEAs can be customized to align with the specific requirements of your application, ensuring optimal performance where it is most critical. Leveraging Heraeus Precious Metals’ proprietary catalyst manufacturing technology, you are enabled to maintain outstanding quality while keeping production costs low. This allows for exceptional efficiency and extended operational life, driven by highly active and durable catalyst layers.

These modular, multi-layer assemblies are engineered for high-volume manufacturing and incorporate proprietary sealing materials that provide long-term protection for the active regions throughout all MEA layers. Integrated into a precision frame using a patented lamination technique, they enable simplified handling and streamlined assembly. Heraeus Precious Metals’ MEAs deliver consistent, high-efficiency performance even under demanding, heavy-duty conditions, maintaining reliability across a broad spectrum of humidity, temperature, and pressure ranges—without compromising service life.

By combining extensive fuel cell design expertise with advanced production capabilities, the tailored MEA solutions are both cost-efficient and performance optimized. Heraeus Precious Metals focus is on helping customers minimize fuel consumption and reduce maintenance costs across diverse application environments.

-

Cost Efficiency: Economical manufacturing processes that reduce overall production expenses.

-

Longevity: Extended performance life for reliable, long-term operation.

-

Customization: Tailored solutions designed to meet specific application requirements.

-

Durability: Ultra-stable catalyst layers designed for prolonged activity and minimal degradation.

-

Application Focus: Designs optimized to align with the functional demands of each use case.

| Actydon | CCM 01, Actydon | CCM 02 | Actydon | MEA 01, Actydon | MEA 02 | |

|---|---|---|

| Membranes | Various thicknesses and additives | Various thicknesses and additives |

| Dimensions | Variable coating widths (Max: 460mm) |

Customized solutions (available on request) |

| Delivery Formats | CCM roll or MEA sheets (samples available) | CCM roll or MEA sheets (samples available) |

To deliver this superior level of reliability at industrial scale, Heraeus Precious Metals and Freudenberg e-Power Systems have combined their unique capabilities in a technical partnership: Advanced precious metals expertise meets leading-edge system oriented process know-how, delivering a complete loop from metal sourcing and financing, product supply, to recycling of platinum group metals.

Your Expert for CCM and MEA

Catalytic Solutions to Boost the Fuel Cell Operation - Balance of Plant

Fuel cells that convert the chemical energy of a fuel and an oxidant directly into electricity, are a key technology in the energy transition – especially as a sustainable decentralized power source.

A variety of different fuel cell technologies exists, characterized for example by their operating principle, the applied electrolyte, their operating temperature or the fuel in use. As varied as the fuel cell technologies themselves are the demands placed on the supporting equipment that enables the cell to function as an environmentally friendly and reliable energy source in the first place.

Beyond our own fuel cell catalysts for PEM electrolysers Heraeus Precious Metals meets these challenges with its efficient catalyst technologies to gas treatment and emission reduction.

For fuel processing Heraeus supplies catalytic solutions for Reforming, Water Gas Shift or Gas Purification e.g. by Preferential Oxidation (PROX) or Selective Methanation – all tailored to the needs of an independent decentralized system operation. Find more details about the Heraeus heterogeneous catalysts in the catalyst selector.

Our long-term experience in emission catalysis at Heraeus Precious Metals enables us to produce efficient and durable and catalysts for your off-gas treatment and a possible energy recovery by catalytic combustion.

Each fuel cell technology has its individual advantages and constraints which eventually define the applications for which a technology is most suitable. Heraeus Precious Metals will support you with our bulk catalysts and tailored catalytic coatings to best adapt the balance of plant to your individual mission.

Your Expert for Catalytic Solutions to Boost Fuel Cell Operation

Read As Well

Get in Touch With Us

Press and News

Dr Michael George and Dr Christian Gebauer, Heraeus Precious Metals, consider the role hydrogen fuel cells could play in the development of heavy duty vehicle materials.