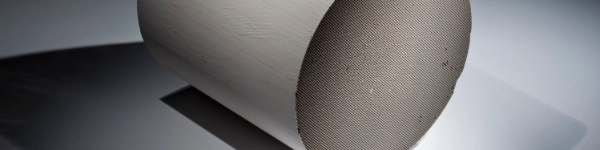

Soot Particle Filter

Soot filters, also diesel particulate filters (DPF), have the task of removing the soot emitted by a diesel engine from the combustion gas. This takes place through monoliths of ceramic materials such as cordierite and silicon carbide with flow channels closed at alternate ends. This guarantees that the exhaust loaded with soot must always flow through a porous wall. The soot particles are deposited on the walls. This is achieved with an efficiency up to 95 percent.

To keep the particle filters effective throughout the life span of an engine, the deposited soot must be removed regularly. This is done by combustion. This so-called regeneration can be carried out with various aids. There are two different types of regeneration: passive regeneration and active regeneration.

- Passive regeneration: Starting at an exhaust gas temperature of 600 °C diesel soot react with the aid of the oxygen in the exhaust gas to CO2 and CO. This rather high exhaust gas temperature rarely is achieved under usual operating conditions.To lower the temperature of the soot ignition coating there can be used catalytic coatings or additives which are charged over the fuel. Further there is the possibility to oxidize the soot continuously by the help of NO2. The necessary NO2 will be forwarded by an upstream oxidation catalyst or directly by the precious metal filter coating.

- Active regeneration: By artificial increasing of the exhaust gas temperature the filter will be, mostly in connection with a catalytic coating, regenerated effectively. On the one hand the increasing of the exhaust gas temperature can be reached by charging of fuel upstream oxidation catalyst because of its catalytic conversion. Further the fuel can be combusted directly with the aid of a burner. Alternatively there is the possibility to heat the exhaust gas electrically. Finally the combination of passive and active regeneration guarantees a safe oxidation of the filtered soot particles.

Get in Touch With Us