Gas Purification Catalysts

Demanding industrial applications as well as stricter environmental regulations necessitate the implementation of efficient gas pre- and post-treatment technologies and solutions. With the HeraPur® catalyst series, Heraeus offers the means of removing impurities from industrial gases that would otherwise be detrimental for your downstream applications or for the environment. Catalysts from the HeraPur® series meet the challenge of converting contaminants from process gases to very low concentrations (in the ppm or even ppb range) and removing climate killers from industrial exhausts.

The HeraPur® Catalyst Series

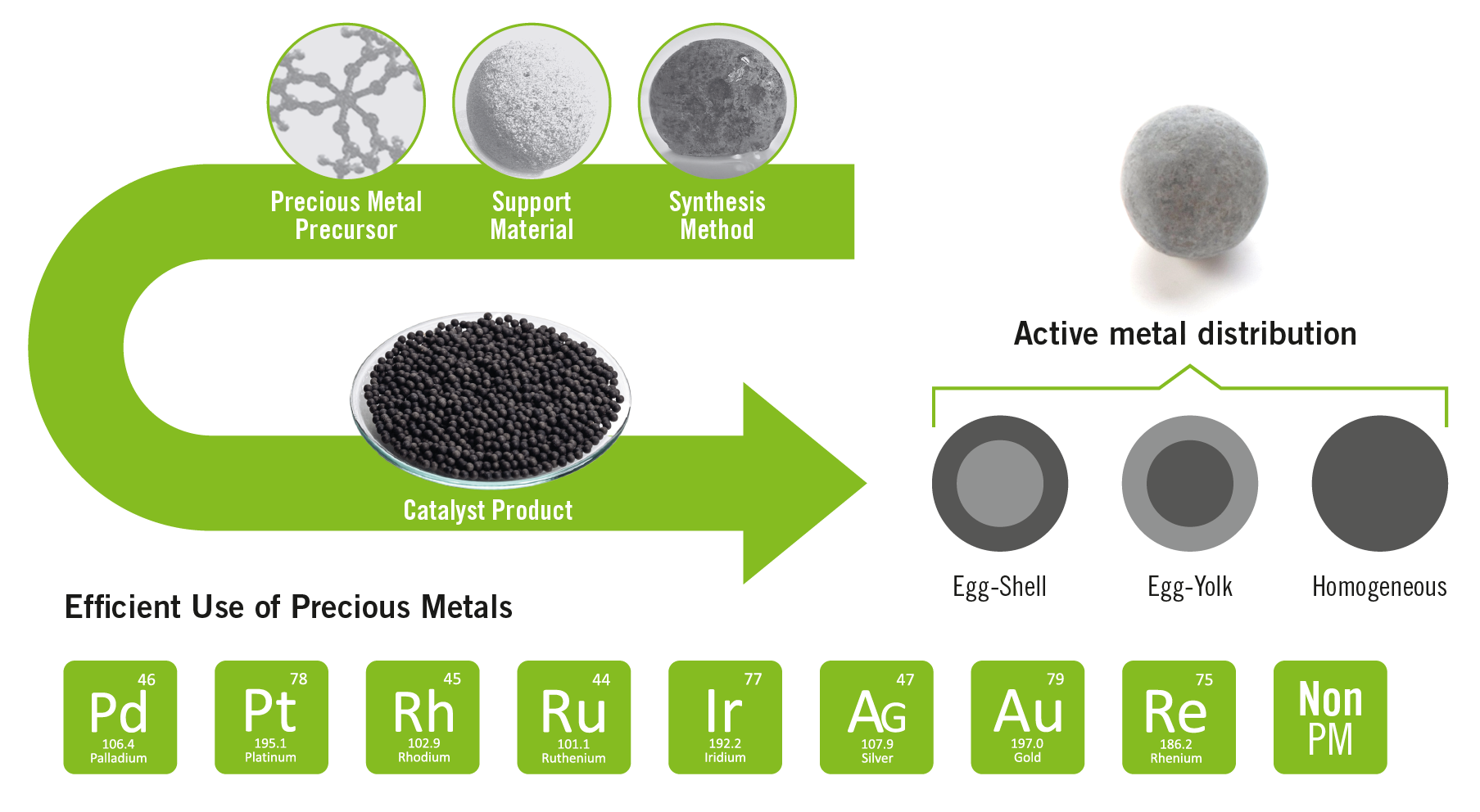

HeraPur® catalysts generally consist of metal oxide supports that are functionalized with precious and/or non-precious metals. A wide range of different carrier materials such as alumina (Al2O3), silica (SiO2), titania (TiO2) or zirconia (ZrO2) are available in a variety of shapes and geometries (tablets, spheres, extrudates, on structured ceramic or metallic supports) to serve a large spectrum of catalytic applications.

Air & Noble Gas Ultra Purification for Technical Processes

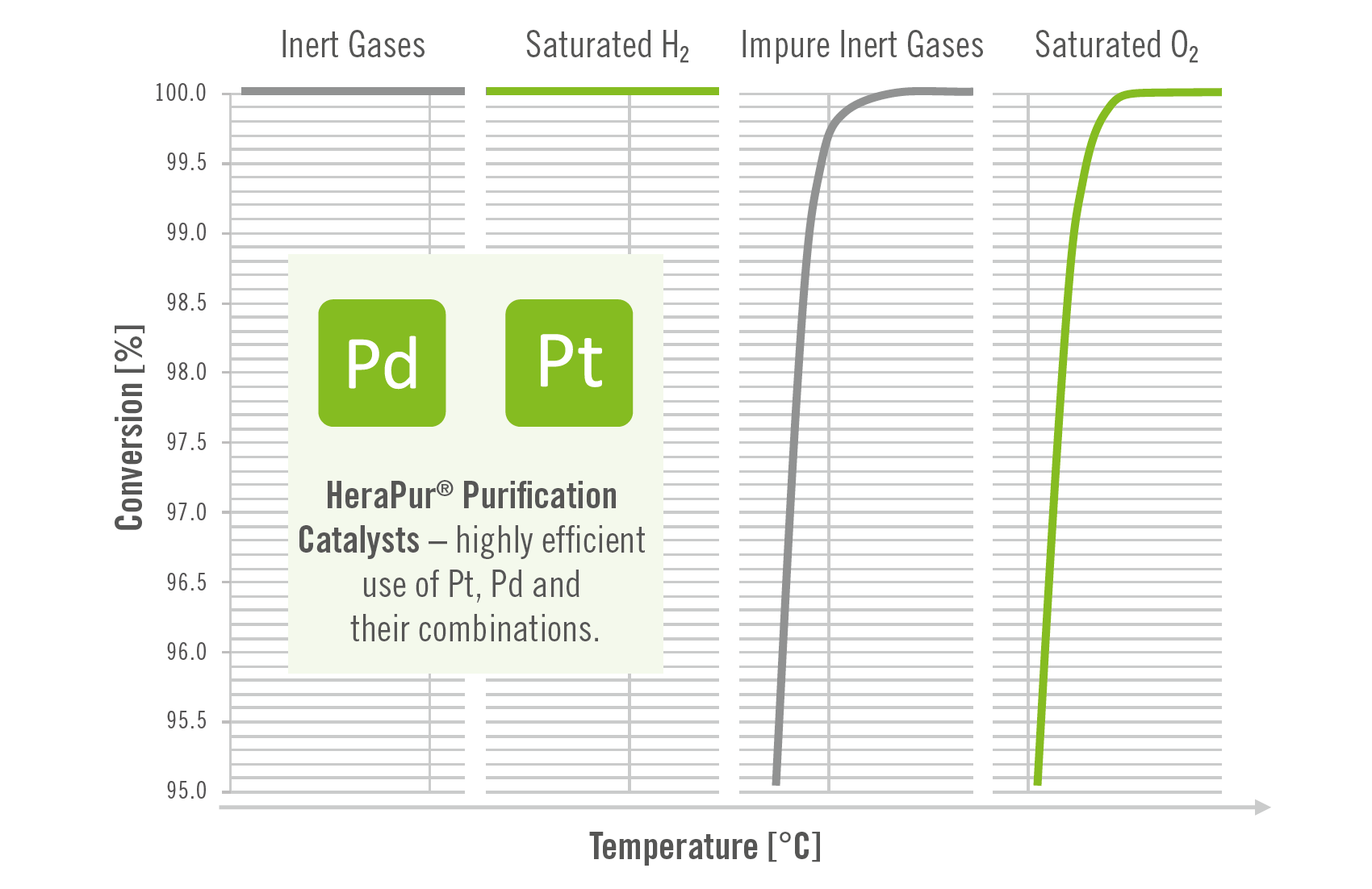

For various technical processes and applications pure and ultra-pure gases are needed, such as air, N2, O2, H2, He, Ar, etc. To achieve the required qualities, a variety of impurities such as CO, H2, hydrocarbons and others have to be removed.Synthetic air, for instance, is a type of industrial gas which is required for countless technical processes in different concentrations and purities. Using Heraeus catalysts in a final purification step ensures a product with extremely low concentrations of undesired constituents. Special catalysts can also be used to treat air and remove traces of CO and hydrogen. In the electronics industry ultra-pure gases, free from CO and hydrogen, are required to produce advanced semiconductors.Furthermore, oxygen even in traces has to be eliminated from technical gases such as nitrogen, hydrogen and noble gases. In a catalytic reaction with hydrogen in traces or as the main component – the oxygen is converted into water vapour, which then can be easily removed e. g. by adsorption dryers if necessary. In the purified gas residual concentrations of oxygen can be achieved down to the ppb range. This kind of reaction can take place at temperatures far below 100 °C or even at room temperature.

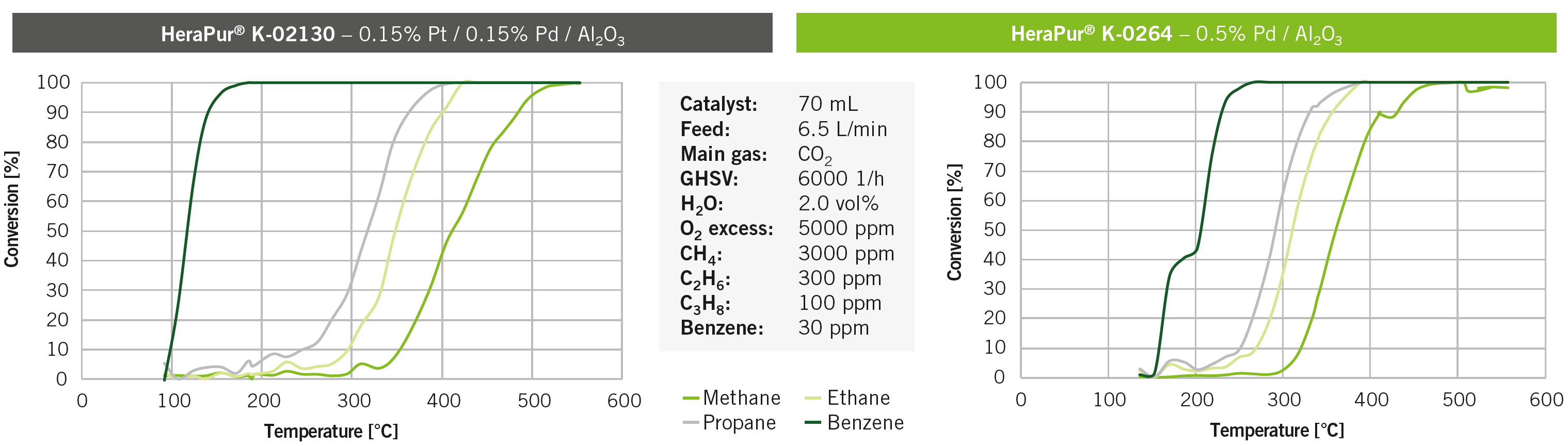

Carbon Dioxide Purification

The food industry in particular, but also other industrial applications, have large requirements for highly purified CO2. In order to achieve CO2 in high-purity, the raw gases from natural wells or chemical plants can be treated with catalysts to oxidize the undesirable constituents. Depending on the source of the CO2, there are many different impurities, such as CO, H2 and hydrocarbons which have to be reduced to a few ppm in most cases or, for example highly toxic aromatic compounds, which even have to be reduced to the ppb range. Heraeus catalysts allow the precise removal of these impurities from carbon dioxide in high quality not only for food grade applications, but for all industries, where highly purified CO2 is needed.

Hydrogen and Oxygen Purification

Hydrogen Purification

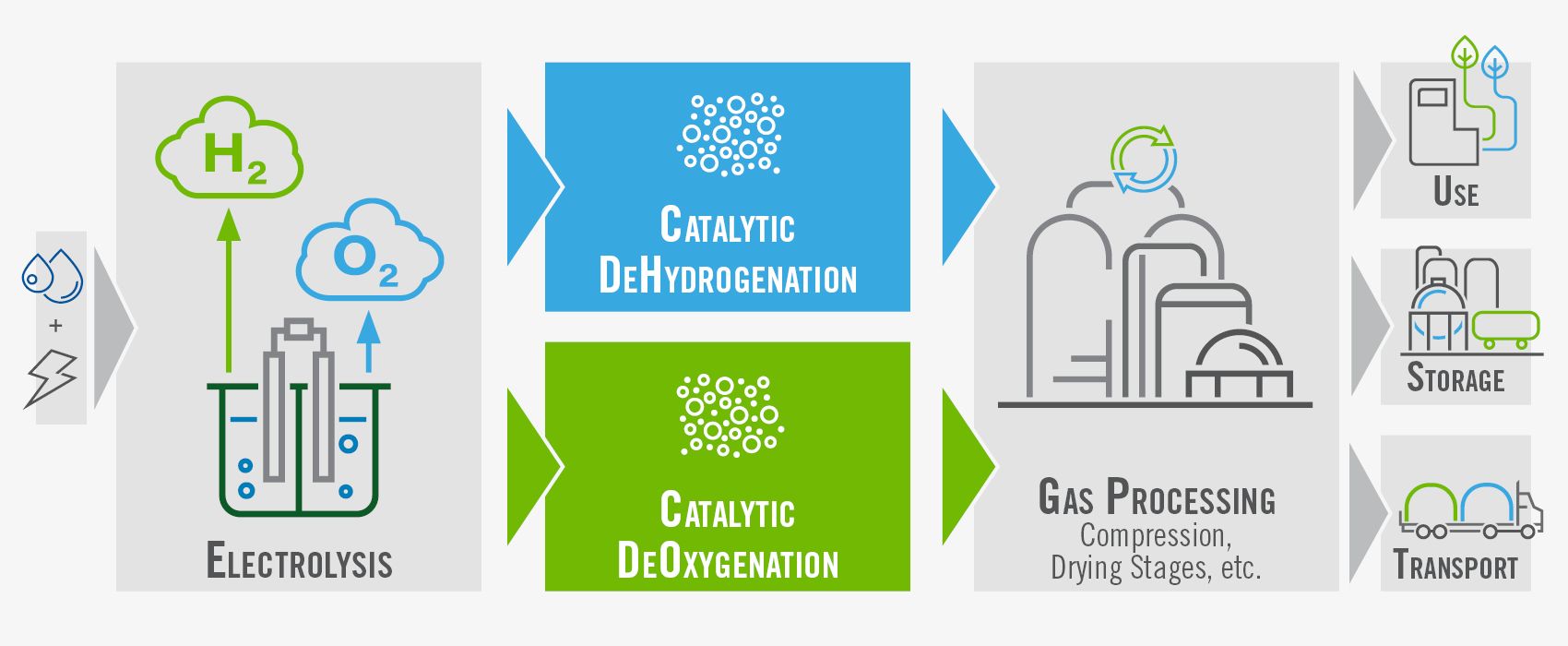

The splitting of water by electrolysis is an efficient technology to produce green hydrogen and oxygen. However, the separation of the gases is not perfect. Depending on the electrolysis technology, a certain amount of one gas may slip into the other. To safely process, transport or utilize the gases, these impurities need to be removed.

Since decades, Heraeus’ gas purification catalysts have reliably fulfilled the task of removing O2 from H2 streams by converting it to H2O – operating at low temperatures and with an efficient use of the applied Platinum Group Metals (PGM). With the emergence of new electrolysis technologies and applications, a new generation of deoxygenation and highperformance dehydrogenation catalysts has been developed.

Hydrogen and Oxygen Purfication of Electrolysis

Heraeus Precious Metals provides catalytic solutions for efficient H2 and O2 removal from different gas mixtures, as shown in an exemplary diagram below. HeraPur® catalysts are characterized by:

- Low temperature removal of O2 or H2 from hydrogen or oxygen respectively

- Different compositions based on Pt, Pd or Pt/Pd alloys

- Low PGM-loadings – especially for electrolysis feeds with low impurity profiles

Hydrogen and Oxygen Refining

HeraPur® catalysts can also be used in gas refining and recycling operations. Here process gases of oxygen and hydrogen can contain other unwanted impurities, such as volatile organic compounds (VOCs) and nitrous oxide (N2O) which can also be successfully removed. HeraPur® catalysts are very effective at preferentially oxidizing carbon monoxide (CO) to carbon dioxide (CO2). This technology can be harnessed to purify hydrogen gas streams in fuel cells, where only extremely low CO contaminations are tolerated. It is equally suitable for hydrogen recycling operations. Via an alternate reaction path different HeraPur® catalysts here can also catalytically convert CO to Methane.

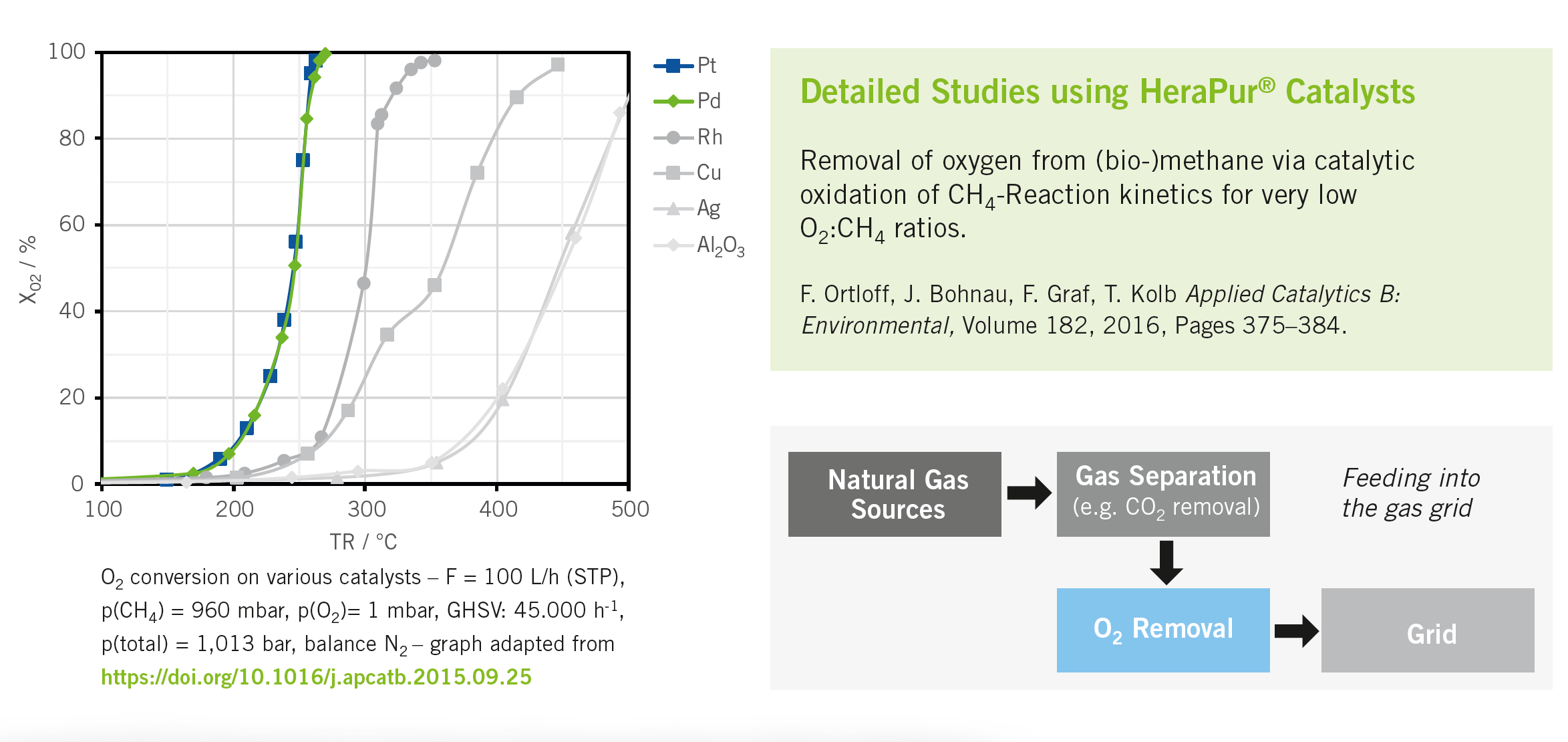

Methane Purification

HeraPur® catalysts facilitate an energy efficient removal of carbon monoxide (CO), hydrogen (H2) and oxygen (O2) from methane (CH4). This can be applied e.g. in biogas upgrading processes at moderate temperatures and with little byproduct formation.

Inert Gas Purification

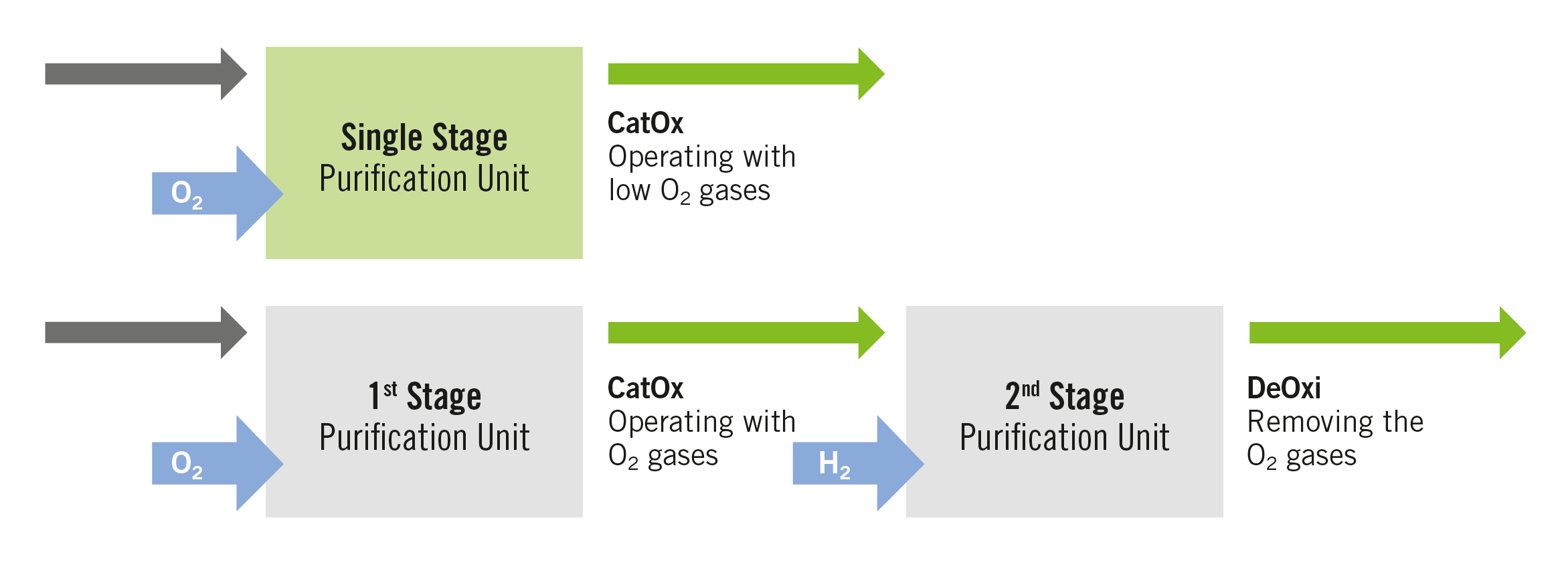

In case inert gases are used in a process as a protective atmosphere large streams of these can be a need of recycling. One example is the treatment of raw materials for plastics, such as in the Solid State Polycondensation (SSP) process for food grade polyester resins. Impurities accumulating in the inert gas here are organic compounds such as aldehydes, glycols and oligomers. Catalytic oxidation is an efficient process to treat the recycled gas stream. HeraPur® catalysts are designed to be implemented in the purification process even with a very small (stoichiometric) oxygen excess. After the catalytic process and the drying treatment the purified gas can be directly recycled to the SSP reactor after a prior drying treatment. Beyond this example Heraeus catalysts are applied to a variety of gas recycling processes and inert gas streams. They can target any organic impurities, provided that they can be oxidized to CO2 and water under process conditions. The process can either run with little oxygen excess or excess oxygen can be efficiantly converted to H2O then in a two stage process.

Emission Abatement

Although there are many methods available for the abatement of emissions of volatile organic compounds (VOC) and CO, the most practical and effective technique for their destruction is incineration or oxidation. In this way, the VOC and CO are oxidized at elevated temperatures to harmless products such as CO2 and H2O. The advantage of catalytic oxidation is the lower temperature required in comparison to thermal incineration. For various industrial processes (e. g. chemical production, printing and painting, food processing, electronics, soil and groundwater remediation) this is a proven and cost-efficient method to control emissions. Due to the lower operating temperatures, the combustion units can be built with less expensive materials and in simpler fashion, resulting in a longer service-life of the plant and at lower operation and maintenance costs. For these applications, we offer catalysts with precious metals or base metals as active compounds on bulk material. For large gas flows and in case a low pressure drop is required, of HeraPur® monolithic catalysts can be offered.

Get in Touch With Us